IBR roofing sheet making machine

Feed frame roller: Stainless Steel

Machine base structure: 350H steel welded

Machine architecture: Middle plate

Feed frame roller: Stainless Steel

Machine base structure: 350H steel welded

Machine architecture: Middle plate

What is the application of IBR roofing sheet making machine ?

IBR roofing sheet making machine cost is mainly producing steel roof/ wall sheet .The final products have two types,corrugated sheet and trapezoidal sheet.As we know, steel roof/ wall sheet is widely used in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing.

Feed frame roller: Stainless Steel

Machine base structure: 350H steel welded

Machine architecture: Middle plate

Drive mode: Chain drive

Rollers material: 45# steel

Shaft diameters: Φ 80mm +70mmSolid shafts

Shaft material:45# steel

Motor power: 5.5kw

Forming speed:0-20m per minute

Power: 380v 50hz 3Phase

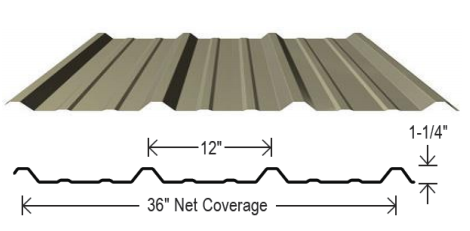

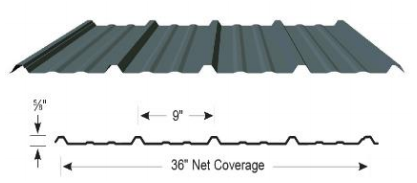

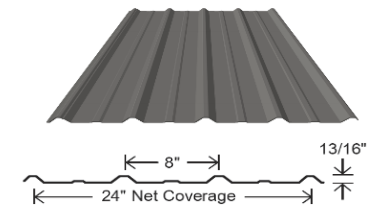

1.Profile drawing

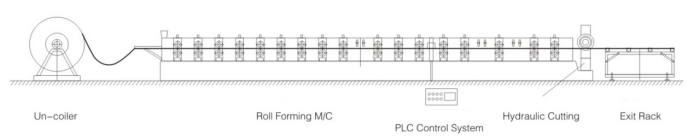

2.Process flow

3.Manual Decoiler

1.Work type: passive type

2.Structure: Steel channel welded for the basic frame

3.usage:To support the coil and make the uncoiling

4.Loading capacity: 5 tons

5.Inner diameter: 450-550mm (manual adjustment)

6.Coil width: 1250mm

7.Brake system: manual brake

4.Main forming machine parameters

1.Feeding device

One set guiding roller

Steel plate welded platform to carry the sheet and feed into roll forming system

Feeding width is adjustable with the handle wheels

2.Rolling shaft

Shaft material:45# STEEL

Shaft diameter: 75 mm

Tempering treatment to prevent deformed and improve hardness

3.Roller

Shaft material:45# steel

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life

Rolling station:16 rolling stations

Work speed: 0-12 m/min {4 pieces per minute (3m per piece)}

Machine structure:Steel plate welded structure

Machine basic frame

:50# H steel welded

Work power:5.5 kw

Rolling spacer: Anti rusty treatment

Pull rod: Anti rusty treatment

4.Transmission

By Chains with cover

Noted: please fill the lube in case the chains getting dry

![]()

5.PLC Control System

Frequency brand: Delta (original)

PLC brand: Delta (original)

Frequency brand: Delta (original)

Screen type: Touch screen, also have buttons on the panel

Screen language:English/Chinese

Cut command: Yes

Profile length set-up: Yes

Batch quantity program: Yes

Low pressure electric part: Schneider brand

Encode: Omron brand

![]()

6.Product Receiving Table

Length: 3 meters

Width: 1.25 meter

Material: Square pipe welded