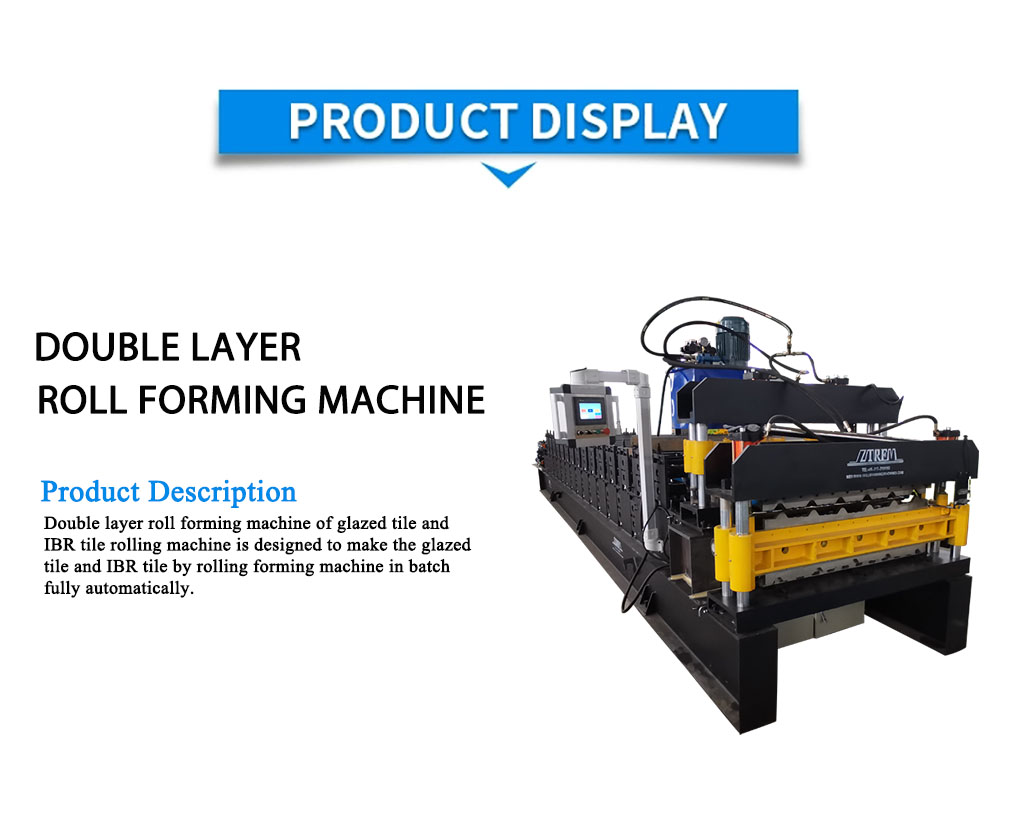

Double layer roll forming machine

Material of the profile: GI or color steel

Thickness range: 0.3-0.8mm

Main motor power:7.5kw, AC motor, motor inside of main machine (Brand:Guomao of China) (according the final design)

Material of the profile: GI or color steel

Thickness range: 0.3-0.8mm

Main motor power:7.5kw, AC motor, motor inside of main machine (Brand:Guomao of China) (according the final design)

Double layer roll forming machine:

Double layer roll forming machine of glazed tile and IBR tile rolling machine is designed to make the glazed tile and IBR tile by rolling forming machine in batch fully automatically. Glazed tile roof sheet Double Layer Roll Forming Machine is widely used in many kinds of industrial factory, civilian buildings, It has advantage of pretty appearance, durable using and so on. By the double layer design, it can save cost and space for the manufacturing.

Detailed parameters of double layer roll forming machine

1.Material of the profile: GI or color steel

2.Thickness range: 0.3-0.8mm

3.Main motor power:7.5kw, AC motor, motor inside of main machine (Brand:Guomao of China) (according the final design)

4.Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase or customized

5. Roller material:ASTM1045 chrome plated surface with chrome,CNC,

6.Shaft diameter: ¢70mm material: SAE1045 with quenching and tempering

7.Machine roll forming speed: not less than 15m/min

8.Transmission: by chain, one inch, single line

9.Roll former has leveling bolts in the base for adjust the leveling

10.Machine base frame adopt H beam welding steel

11.In the main Roll Forming Machine have 2 buttons for urgency stop if happen any malfunction.

12.Machine adopts new station to make machine more strong

13.To avoid accidents, all of drive part adopt protect cover

14.Color of machine: Blue and yellow (or base on customer request)

Detailed parameters of double layer roll forming machine

1.Material of the profile: GI or color steel

2.Thickness range: 0.3-0.8mm

3.Main motor power:7.5kw, AC motor, motor inside of main machine (Brand:Guomao of China) (according the final design)

4.Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase or customized

5. Roller material:ASTM1045 chrome plated surface with chrome,CNC,

6.Shaft diameter: ¢70mm material: SAE1045 with quenching and tempering

7.Machine roll forming speed: not less than 15m/min

8.Transmission: by chain, one inch, single line

9.Roll former has leveling bolts in the base for adjust the leveling

10.Machine base frame adopt H beam welding steel

11.In the main Roll Forming Machine have 2 buttons for urgency stop if happen any malfunction.

12.Machine adopts new station to make machine more strong

13.To avoid accidents, all of drive part adopt protect cover

14.Color of machine: Blue and yellow (or base on customer request)