Door shutter roll forming machine

Material: Galvanized Coil

Material Thickness: 0.8-1.2mm

Main roll forming machine Power: 7.5 KW

Forming Speed: 4-7m/min

Material: Galvanized Coil

Material Thickness: 0.8-1.2mm

Main roll forming machine Power: 7.5 KW

Forming Speed: 4-7m/min

Aluminum window sill roll forming machine

aluminum window sill prevents moisture, leakage and splashes, and staining by draining rainwater away from them. The system comprises a purpose-made aluminum drip, with its easily recognizable rounded edge that rolls formed by roll forming machine. Window sills are designed to be installed together with windows into the bottom part of the window opening.

Rolling Shutter Machine Technical Proposal

Summary

Material: Galvanized Coil

Material Thickness: 0.8-1.2mm

Main roll forming machine Power: 7.5 KW

Forming Speed: 4-7m/min

Dimension: 7×0.8×0.8 m (L*W*H)

Weight: 4-5 T

Main Parts

Manual Decoiler

Roll Forming System

Hydraulic cutter

Control system

Output table

Working Flowing

Manual Un coiler — > > Feeding — > > Roll Forming — > > Cutting — > > Output table

Roller door roll forming machine

Technical Parameter

Decoiler

Decoiler Type: Manual

Loading capacity: 3Ton

Impassive to expanding

Roll Forming system with feed panel unit

Axis Diameter: 65 mm

Forming Roller station: 12 groups

Main Axis material: First grade 45# steel

heated and quenched

Roller material: GCR15,

Hard Chrome Coated,

heated and quenched

Pillar Steel Pillar

Forming Speed: 12-15 m/min

Drive Type: 80# CHOHO CHAIN

Machine Frame stand Integrated design new generation

Cutting Device

Cutting type: Hydraulic cutting

Cutting system power: 2.2KW

Cutting length tolerance: ±0.5mm

Electrical System

PLC system: Delta

Length Controller: Delta

Operation: Delta Touch Screen

Inverter: Delta

Run-out Table

Table quantity: 1 pcs*6m length

Structure: Angle bar welded

door-shutter-making-machine

Roll up Shutter Door

Rolling Shutter Doors is one type of door or windows shutter consisting of many horizontal slats. The door raises to open it and lower to close it. fast rolling shutters are rapid and space saving doors appropriate for any applications such as structural context and industrial part. the door can be open manual or motor.some of roller shutters such as PU Rolling Shutter can use as a method of insulation that can protect against hail damage and withstand high winds.

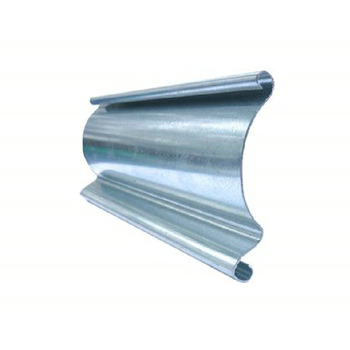

single section type (single layer):

single layer slat is like S shape and will fabricate by roll forming machine from steel strips. one side is male and another side is female joint, to connect all together and make door or windows.

this type of shutter mostly using for garage and store doors. manufacturing single layer shutter slat takes less than 2 months, and it has near 10 to 15 roller stand, so operating and fabricate shutter will be fast and convenient.

furthermore, shutter installation is really simple with easily repair service. Single-layer shutter slat has so many patterns based on usage and customer requirement. finish slat width is in 40 mm to 200 mm, with thickness 0.5 to 1.5 mm. so as to result you can imagine we have a thousand forms of single-layer shutter that all can manufacture by roll forming machine.

Double shutter or PU foamed shutter machine:

For fabricating polyurethane shutter slat we need complete line (roll forming, PU foam machine, furnace tunnel, output table and so on). Roll forming machine that can manufacture acceptable PU shutter should have more than 30 stand roller with proper roller design.

GEIITFORMING carrying more than 15 years’ experience that can assure quality and delivery time for global and domestic customers. recently GEIT workshop output is more than 15 sets of a complete line of polyurethane door shutter each month.

Pu foamed door and window shutter

for rolling up and down it has less noise and working more silent it means each day less damage on the joint part of the shutter and longer performing, meanwhile in some crowded area will be more suitable with human care.

polyurethane shutter doors and windows are sound absorbers, so once you rolling down most of the street sounds will absorb by foam inside shutter.

fireproof and energy-saving: the density of foam will help to save area energy and also its anti-fire. so it’s really highly recommended for main doors and windows to make safer and economic rooms. As result, we can say the best door and windows shutter is PU foamed shutter.

Door shutter roll forming machine:

These machines are very different quality and speed, as kind of rolling shutters you should use different machinery.

Some machines named roll-forming machines are rolling steel coil and step by step forming steel and finally, cut it as need size.

For installation rolling shutter machine, you need about 15meter length and 5-meter width, also 3 phase power.

Roll Forming Machine for making Rolling Shutter Strips are 2 types:

• Gearbox rolling shutter machine

• Chain rolling shutter machine

Some of the rolling shutter machines are work with gearbox and some others are a chain. chain type is chipper kind and can form steel max 1.25 mm. if you want to use steel roll more than 1.25 mm you have to select gearbox type. This type is expensive but has very good quality and speed. Some of customer need quality and some others need cheap price, which one are you?