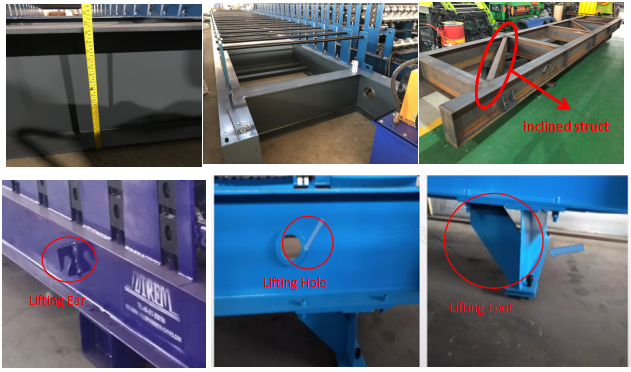

The material of basic frame of our company are 350#, 400# or 500# H-beam steel welded, and its height will be 350, 400, 500mm. Compared to other

merchants using U-shaped steel, we use H-shaped steel. U-shaped steel is unstable and easily damaged during use and transportation.The advantage

of H-shaped steel is that it will be more stable and not damaged easily during the production and transportation process.

Our company also sets up inclined struct in order to improve the strength of frame. These structures can improve the stability of the product, thereby

reducing damage and extending its service life. Our frame is not easy to bend and deform even after being moved and hoisted many times. It is not easy

to be damaged during transportation and can remain stable. Some manufacturers' large racks are deformed during transportation, and their levelness is

affected. As the machines are assembled before delivery, there is no way to repair them, which will cause serious consequences that the whole machine

can't run normally, and it will seriously affect the usage of product and the progress of the project.

Only when the big frame is strong enough can the machine always operation smoothly. If the big rack is not strong enough, the machine will be affected

in the subsequent production process. Therefore, our big frame is thick, welded firmly, and has a large volume and weight. We enlarged the self-weight

of the big frame, and used the diagonal brace that matched with our own. Our roof tile roll forming machine has lifting ear, lifting hole and lifting foot

which convenient for loading. At the same time, it can ensure that collisions are avoided during transportation. The above are the advantages of our

company's equipment. Welcome to inquire and order.

English

English اللغة العربية

اللغة العربية